MAJA

Contact: Mr. Li

Mobile: 13817371428

Landline: 021-69896133

Website: www.shmjkj.com

Address: Qingpu District, Shanghai Green Pine Road 3562

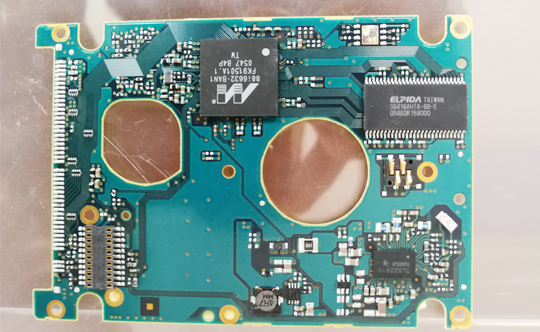

With the progress of science and technology, electronic products are getting lighter and thinner, relatively smaller electronic components are getting smaller and thinner, even the thickness of the PCB circuit board (PCB) is getting thinner and thinner, 0.5mm is that I know the current PCB PCB thickness, such thin PCB circuit board through the SMT Reflow (reflow oven) high temperature, it is very easy due to high temperature plate deformation, and even parts fall furnace problems.

To overcome this problem, clever engineers came up with the idea of using Reflow Carrier to support the PCB board to reduce PCB board distortion. A large part of the PCB board deformation is due to high temperature soften the FR4 plate, so long as you find a material with the following characteristics, can be used as a furnace tray:

Its softening degeneration temperature should be higher than 300 ℃, can be reused, will not be deformed.

Material to be as cheap as possible, and can be mass-produced.

Material can be processed.

Material should be light.

The material is not easy to absorb heat.

Less heat shrinkage.

In the past we almost always use aluminum alloy (also have high carbon steel, magnesium alloy) to make a furnace tray, although Shanghai electronic products processing aluminum alloy lighter than the average iron, but the production line girl picked up a little bit Heavy, but also easy to absorb the heat of aluminum alloy material, after the furnace to be insulated gloves or wait for a cooling time after the pick up, the operation a bit to it is not very convenient.

In recent years, a new material is gradually being widely used in SMT Reflow Carrier to replace the aluminum alloy tray, this material is called synthetic stone, which is basically a compound made of high temperature resistant glass fiber, which can resist up to 340 ℃ above, and can be used for CNC machining, a certain degree of hardness, not easy to deformation, and aluminum than the heat does not end, after the end of the furnace can be hand contact immediately after; endothermic heat there are other benefits, engineers Easier to control the temperature in the reflow oven to achieve the best parts to eat tin quality.

The price of synthetic stone cheaper than today's high aluminum alloy, but this synthetic stone intolerant than aluminum alloy reusable, usually about the reusable about 10,000 times the reflow cycle.

The advantages of using the tray:

Can reduce PCB over-reflow furnace due to high temperature softening caused by deformation.

Can be used to carry thin PCB or FPCB (soft board) pieces and over the reflow oven.

Can be used to carry irregular shape PCB and over the furnace

Can carry multiple PCB over the furnace, increase production.

Phone:+86 21-69896133 A company site: Qingpu District, Shanghai Green Pine Road 3562

Two companies: Anting Town, Shanghai Caoan Road 4514, Lane on the 3rd